Enhance Quality Control with MapSuite, by chipping and scratch recording

In the dynamic world of semiconductor manufacturing, preventing wafer chipping and scratches is paramount to ensuring product quality and reliability. With MapSuite, you can leverage substrate maps to record and mitigate defects, ensuring that only pristine dies make their way into final products.

Understanding the Impact of Wafer Chipping and Scratches

Wafer chipping and scratches pose significant challenges in semiconductor manufacturing, leading to yield loss, reduced product reliability, and increased production costs. Identifying and addressing these defects early in the manufacturing process is essential to prevent their propagation into final products.

Introducing MapSuite’s Quality Control Solutions

MapSuite offers advanced quality control solutions designed to streamline defect detection recording, and mitigation processes.

Join the MapSuite Revolution

Experience the power of quality control with MapSuite. Enhance defect detection, prevent defects in final products, and optimize production processes with our industry-leading solutions. Whether you’re producing wafers or other substrates, MapSuite empowers you to achieve excellence in quality control and defect mitigation.

Discover MapSuite today and revolutionize your approach to manufacturing. Contact us to learn more about MapSuite’s quality control solutions and start maximizing your manufacturing potential.

Key Features of Mapsuite for Defect Registration

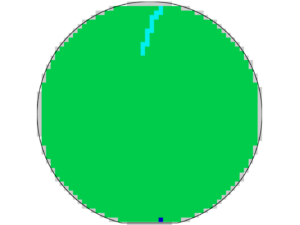

Record Defects: MapSuite enables users to create detailed substrate maps that record instances of wafer chipping, scratches, and other defects. By accurately documenting defect locations and characteristics, manufacturers can track defect trends and implement targeted corrective actions.

Prevent Defects in Final Products: By integrating substrate maps into production workflows, MapSuite helps manufacturers prevent defects from propagating into final products. By identifying defect-prone areas early in the manufacturing process, MapSuite empowers manufacturers to implement preventative measures and optimize yield.

Real-time Monitoring: MapSuite offers real-time monitoring capabilities that allow manufacturers to track defect occurrences and trends throughout the production process. With instant access to substrate maps and defect data, manufacturers can proactively address emerging issues and minimize production disruptions.

Analyze Root Causes: MapSuite provides support for analyzing root causes of wafer chipping and scratches, enabling manufacturers to identify underlying process inefficiencies and implement corrective actions. By addressing root causes, manufacturers can prevent future defects and optimize production processes for improved yield and quality.